This post is part of a spin-along through 51 Yarns by Jacey Boggs Faulkner, in the Wool n’ Spinning community. For other posts in this series, check here.

Now we are getting into the more esoteric fibers. If you’re like me, you feel a little strange about ingredients in your food or clothing that you don’t understand. Clothing isn’t going to have polysorbate 60, but I have found myself over the years wondering… what is rayon? I assumed for the longest time that it was just another form of polyester. Turns out it’s not: it’s a natural fiber, made from wood pulp.

At the yarn store, some yarns and fibers now have some edgy sounding new natural fibers: seacell (from seaweed), milk, soy, rose, bamboo. What are these cool, mysterious fibers? Well, it turns out they’re pretty much rayon.

Rayon and the other “new rayons” made from other stuff are made by extrusion. An extruder is basically a large fancy pasta maker. These materials – seaweed, soybeans, rosebushes, whatever – are pulped and turned into some kind of soup, using I know not what additional chemicals, and forced through tiny holes into long strands. These strands for some reason cohere, making them spinnable fibers. These can be cut and processed into spinning fibers, or blended with other fibers.

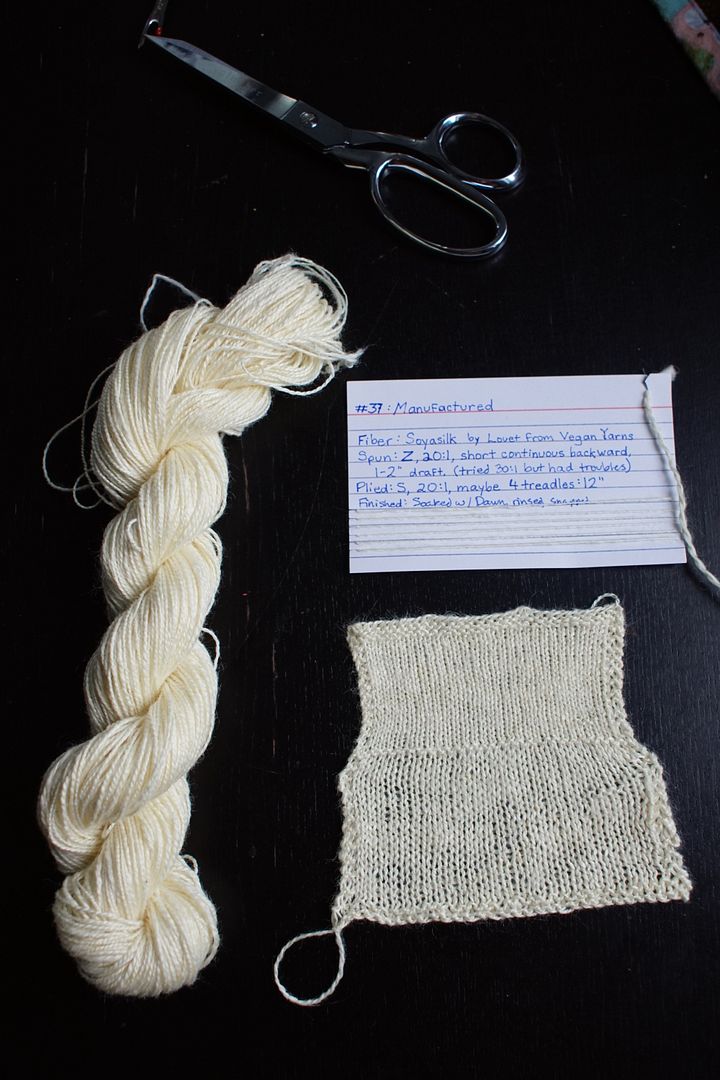

After years of thinking that “seacell” and “rose fiber” must be something novel and super-green, I was a little disappointed when I figured out (years back) that it was just a sub for wood pulp. So I was not expecting to like this fiber. I bought Soyasilk from Vegan Yarns, and did not expect to enjoy spinning it on its own.

I was very pleasantly surprised. Having low expectations was a big help! Maybe because I had just spun cotton, which was a big challenge, spinning Soyasilk came easily. I stripped it my top into quarters and spun it short continuous backward, at 20:1, with maybe a 2-inch draft. It reminded me of longwools, like Wensleydale, in that I had to hold my hands further apart than usual, and there wasn’t any crimp to speak of. But of course this was much finer than longwools, and took a good bit more twist.

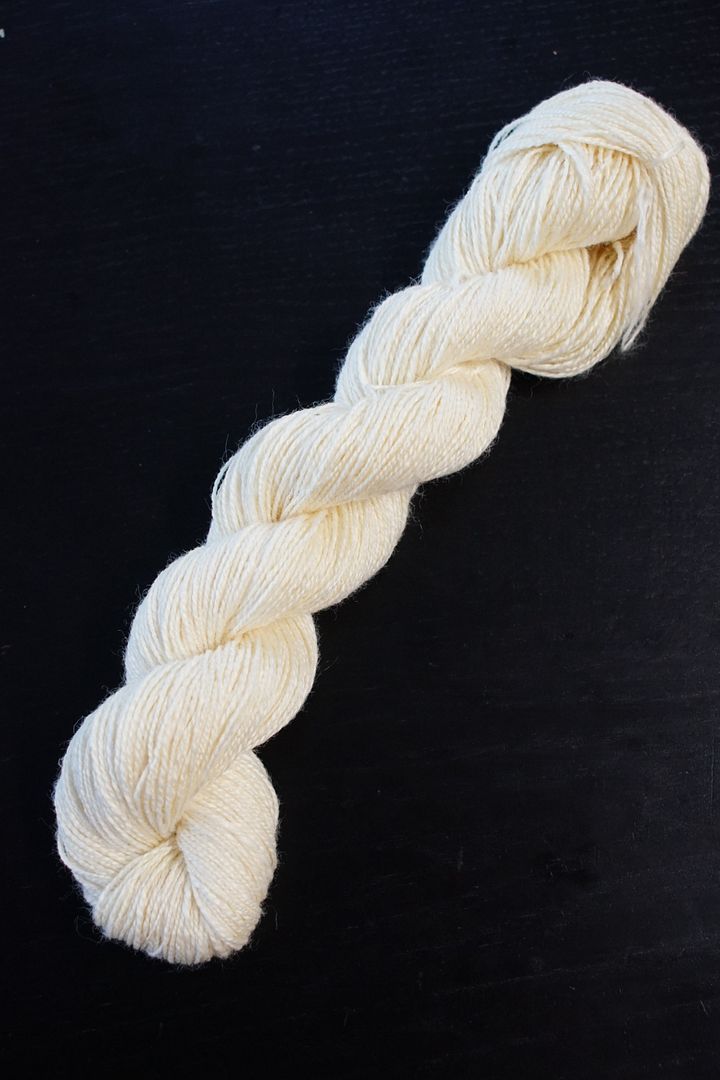

The final yarn feels like something in between silk and acrylic. It has that crunch to it, and I can’t quite decide if it’s pleasant or not.

Like my cotton sample, which was identical in construction and WPI, it looked much nicer at a tighter gauge. Unlike the cotton, the difference between the swatches on US 2s and US 3s was much more noticeable. Cotton at least has some crimp to it, I guess, letting it stretch around the needle, then spring back and poof out to fill those spaces. Soyasilk and other rayons have zero crimp or elasticity. This is even more obvious when you look at the finished skeins untwisted: off the same niddy noddy, the average wool sample hangs around 22”; the cotton hung around 27”; the Soyasilk was 29”.

I won’t be spinning any rayons on their own again; they are not really my cup of tea. But I might try blending some into some wool sometime when I need something cooling and drapey. I was surprised at how fun it was to spin, and would like to learn more about the chemistry of its production.

2 thoughts on “37 of 51 Yarns: Manufactured Soyasilk”